Add to Cart

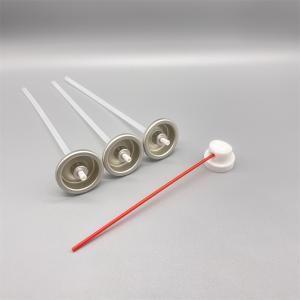

Smart MDF Kit Valve Activator for IoT-Enabled Process Monitoring with Digital Feedback

Product Description:

Step into the future of industrial automation with the Smart MDF Kit Valve Activator. This advanced electromechanical actuator is equipped with integrated sensors and a digital communication interface, transforming a simple valve operator into a intelligent node on your Industrial Internet of Things (IIoT) network. It provides not only precise torque and positional control but also real-time feedback on critical parameters such as position, torque, temperature, and cycle count. This wealth of data enables predictive maintenance, as the system can alert operators to abnormal conditions like rising torque (indicating a stuck valve) or excessive cycles before a failure occurs. The MDF Kit Valve Activator can be seamlessly integrated into modern SCADA, PLC, and asset management systems via standard protocols like Profinet, EtherNet/IP, or Modbus TCP. This allows for centralized monitoring and control of thousands of valves across a facility, optimizing entire processes rather than individual components. By enabling data-driven decision-making, this smart actuator reduces unplanned downtime, extends equipment life, and enhances overall operational intelligence. It is the ideal solution for modern plants aiming to implement Industry 4.0 principles and achieve new levels of efficiency and connectivity.

Bullet Points:

Enables IoT-enabled process monitoring with real-time data on valve status.

Provides digital feedback for position, torque, temperature, and cycle count.

Supports industry-standard communication protocols for easy system integration.

Facilitates predictive maintenance to prevent costly unplanned downtime.

Allows for remote configuration and diagnostics via a network connection.

Specific Application Scenario

In a smart chemical plant, this activator is used on a critical reactor feed valve. It continuously reports its position and torque to the control room, allowing operators to detect a potential blockage in the line before it causes a process deviation or shutdown.

Factory Production Floor

The assembly of these smart activators involves a dedicated electronics section where PCBs are populated and tested. Each assembled unit undergoes a "burn-in" test where it is connected to a network, and all its digital feedback functions are validated against calibrated standards.

Packing and Transportation

The smart activator is first wrapped in an anti-static bag to protect its electronic components. It is then placed in a box with custom foam inserts. The packaging includes clear labels indicating the presence of sensitive electronics.

FAQ

1. What kind of data can I access through the digital feedback?

The digital feedback provides real-time information on valve position (0-100%), output torque, internal temperature, total operational cycles, and health status alerts.

2. How does this actuator enable predictive maintenance?

By monitoring trends in torque and cycle count, the actuator can alert your maintenance system to potential issues, such as valve stem wear or seal degradation, allowing for scheduled repairs before a failure occurs.

3. What networks does it support for IoT-enabled process monitoring?

It typically supports common industrial protocols like Profinet, EtherNet/IP, and Modbus TCP/IP, making IoT-enabled process monitoring accessible on most modern control platforms.

4. Is specialized software needed to configure the actuator?

Basic configuration can often be done via the network using a web browser. For advanced parameterization, free configuration software is typically provided by the manufacturer.

5. Can it operate if the network connection is lost?

Yes, it will continue to operate based on its last received command. All critical operational data is stored locally and can be transmitted once the network connection is restored.